Aashish Infrastructure

Our state of the art manufacturing unit spreads across a sprawling area 5000 sq.ft and a storage area of 2500 sq. ft and accommodates various machines and equipment to manufacture a wide range of sheet metal pressed components and automobile seat frame assembly. The sophisticated machines used by us in manufacturing processes are based on latest technology and assures fast and reliable products.

Separate areas have been demarcated for storage of raw materials, materials in process and finished goods. Transportation of products is effected in company owned vehicles.

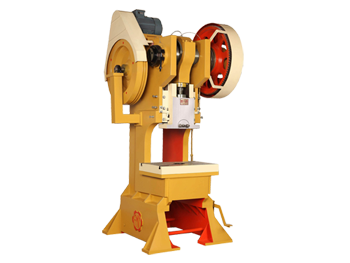

The factory also has its own press shop supported by an efficient tool repair facility.

- Power Supply 50 HP with 160 kva generator

- 10 Power Press (Up to 200 Tons)

- 3 Hydraulic Presses (Up to 250 Tons)

- Arc Welding

- CO2 Welding & Projection Welding

Electroplating

- All types of Plating such as Zinc , Nickel Chrome , phospating etc components supllied to.

- Brazing: We get it done through sub-contractors and we have a plan of Brazing operation in house in future.

- Welding: We have ARC Welding & Projection Welding machine facility.

MASTER LIST OF MACHINES (DOC. REF: AAC-QSD-7510-01)

| Department: M/s. Aashish Auto Components (Metal Stamping Division) |

| Machine Description |

Make |

Model |

Capacity |

Connected Load (HP) |

Year of Installation |

POWER PRESS |

MANKOO |

--- |

100 Ton |

10 HP |

1997 |

| BURMANI |

--- |

75 Ton |

5 HP |

1995 |

| MACHIN |

--- |

60 Ton |

5 HP |

1996 |

| SAKTHI |

--- |

30 Ton |

2 HP |

2001 |

| SARADA |

--- |

25 Ton |

2 HP |

1996 |

| SARADA |

--- |

10 Ton |

1 HP |

1994 |

| VIVEK M/C TOOL |

--- |

50 Ton |

5 HP |

2005 |

| VIVEK M/C TOOL |

--- |

30 Ton |

3 HP |

2005 |

| VIVEK M/C TOOL |

--- |

30 Ton |

2 HP |

2008 |

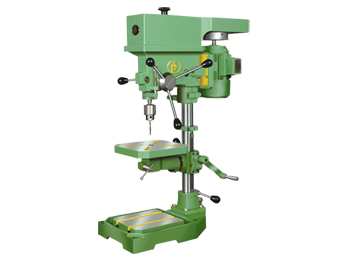

DRILLING MACHINE |

M.T.T |

--- |

1/2'' |

1 HP |

2000 |

| SEW |

--- |

25 MM |

1 HP |

1996 |

SURFACE GRINDER |

A.V.R.O |

--- |

16'' X 8'' HYDRAULIC |

2 HP |

1992 |

| M.T.T |

--- |

12'' X 8'' MANUAL |

1 HP |

1992 |

|